Pellet machine is a highly efficient granulation device widely used in pellet production lines. It can bring economical benefits by processing waste raw materials into fuels suitable for combustion or animal feed. It can be divided into two types by die design: flat die pellet machine and ring die pellet machine. In small and medium-sized production, the flat die machine is superior to the ring die machine based on its unique advantages of easy operation, low consumption and competitive price. Compared to the ring die pellet machine, the flat die pellet machine has the following outstanding advantages.

Low breakage discharging way

The flat die pellet machine can uniformly feed the raw materials and directly enter the crushing chamber according to its own gravity. The pellets are produced by mutual extrusion of the flat dies and the roller. The ring die pellet machine uses a forced feeding method. The raw material is rotated into the granulation chamber by high speed, and then the scraper in the machine distributes the raw materials. This feeding method cannot be uniformly fed, and is not as good as a flat die machine.

Variable pressure

For molds of the same diameter, the rollers of the ring die are limited by the diameter of the die, so the pressure is limited. However, the flat die pellet machine does not have this problem. You can expand the inner bearing space and choose a large bearing to increase the bearing capacity, which not only increases the pressure of the roller, but also extends the service life. Through variable pressure, the flat die pellet machine can process a variety of materials, especially coarse fiber materials such as sawdust, straw, and peanut shells. However, for an annular die pellet machine, due to its unadjustable pressure, the rolling bearing may be worn or broken to compress the coarse fiber material.

Low damage discharge method

The ring die pellet machine belongs to high speed and has a high material damage rate. Compared to the ring die pellet machine, the flat die pellet machine has a low speed rotation, so the damage is small. In addition, the flat-mold sawdust pellet machine can make the pellets surface smoother and the pellets burning rate higher.

Greater liquidity

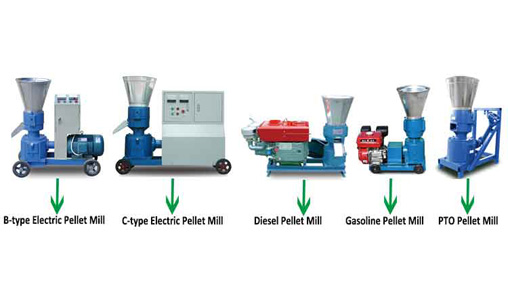

The ring die pellet machine has a large structure and is therefore difficult to move. The flat die pellet machine has a small space and can be moved at will to facilitate granulation. In addition, the portable flat die pellet machine wears less than the ring die pellet machine. As the flat die feed pellet mill has a small size and compact structure, the maintenance and repair would not be any big problem. Small and light weight, which can be used in home,small farm,and light industrial.

Flat die pellet machines are characterized by low energy consumption, high efficiency, and favorable price, which are becoming more and more popular in the market. For small-scale family workshops, this is worth investing. We export more than 80% products overseas. All of our pellet mills meets the highest standard. We adopt high quality raw materials to produce our pellet mills. TICO pellet mill has the features of scientific design, reliable quality, compact structure, small friction, low energy consumption, high yield and low cost and etc. TICO has its own unique and rich corporate culture for over years.

We sincerely waiting for you and welcome our customers to visit our company!