pellet packing machine

Pellet packing machine introduction

Automatic pellet packing machine, also called pellet bagging machine, is used to weigh and pack biomass pellets automatically. Generally, pellet packing machine is necessary in the large and medium biomass pellet production line, the whole process is controlled by computer, can weigh and pack automatically, not only suitable for biomass pellets, but also for granulate and powdery materials with good fluidity, such as the rubber particles, chemical particles, grains, fertilizer particle and so on.

The materials of bags for packing can be plastic, kraft, woven, sack, and paper-plastic compound. The series processing like automatic weighing, packing, conveying and sewing can be accomplished at one time. It’s necessary and helpful for large scale biomass pellet production line to use an automatic pellet packing machine, which can save your time and reduce the cost.

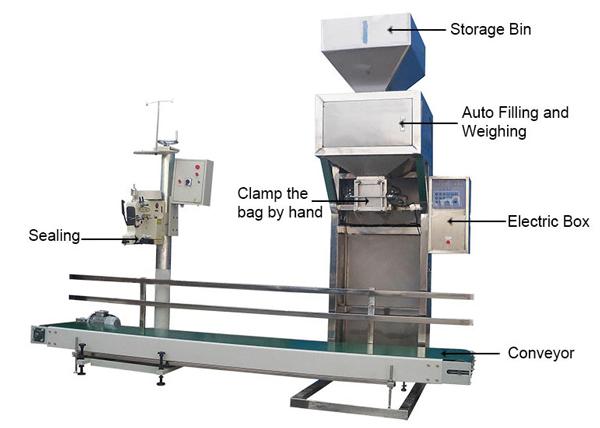

Configuration of automatic pellet weighing and packing machine

The main configuration of automatic pellet weighing and packing machine is weighing system, storage bin, conveyor, packing system and an intelligent controller. The storage bin is used to store the raw materials temporarily. And as the name implies, weighing system is used to weigh the quantity of the pellets and other particles. The conveyor is to transmit the packaged bags from the weighing system to the sewing system with the length of 3 meters. And with the intelligent controller, can make sure the weighing and packing machine works automatically and accurately.

Specifications of automatic pellet weighing and packing machine

| Model | DCS-Z-W-50 |

|---|---|

| Components | Main scale body, Control system, 3-meter conveyor, sewing machine |

| Feed type | Double speed gravity feed |

| Clipping way | Double cylinder belt cliping |

| Weighing range | 5-50 kg |

| Weighing accuracy | ±0.2% |

| Weighing speed | 200—300 bags/h |

| Height | 222cm |

| Power consumption | 1.0Kw |

| Compressed air consumption | 0.4-0.6Mpa compressed air 1m^3/h |

| Application scope | Granular materials with good fluidity |

Characteristics of pellet weighing and packing machine

- With the user friendly operation interface, which can be connected with computers for data communication.

- The automatic calibration can be realized by the intelligent meter, what’s more, the error caused by long-term use and temperature change can be reduced.

- The integrate circuit ensures high stability and reliability. The high-precision sensor, pneumatic actuator ensures easy maintenance and non-pollution.

- The whole procedures like feeding, weighing, bagging, conveying and sewing are controlled by computer, suitable for woven bag, cloth bag, sack paper bag and plastic bag etc.

- The main body is made of carbon steel, painted with plastic. The material contact parts adopt stainless iron, resistant to corrosions.

- It is easy to operate, and can work continuously with automatic control parameter setting and automatic correction.

- This weighing and packing machine has perfect exhaust system and good sealing performance, can realize double seal, to prevent leakage of materials and ensure high purity of products.

- The pellet packing machine can be customized according to the customers’ requirements, with the special design can guarantee the fast packaging and high packing precision.