counterflow pellet cooler

What is counterflow pellet cooler?

In the large and medium scale of biomass pellet plant, cooling of the pellets is necessary. Because when the pellets are made by the pellet machines, the temperature is high up to 70-90 ℃ and the moisture is 17-18%. they are soft and the hardness isn’t enough and they can’t be weighed and packed and stored immediately. Therefor, counterflow pellet cooler is the excellent equipment to cool the finished pellets, it can lower the temperature of pellets quickly and efficiency, to increase the harness and reduce the water content. And after cooling, it is more convenient to store and transport the pellets.

Specifications of counterflow cooler

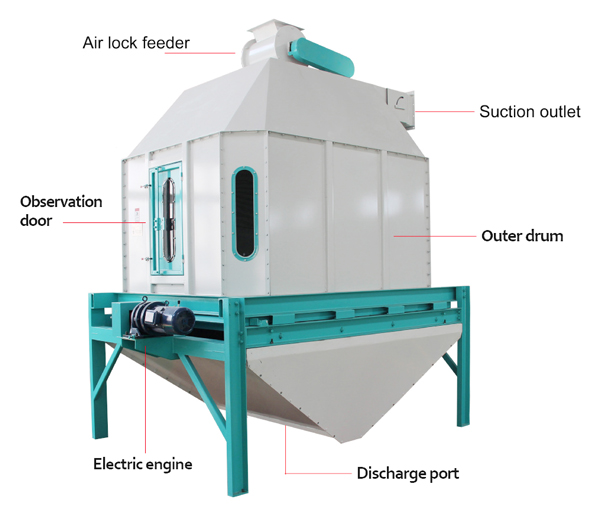

The main components of a counterflow cooler are air-lock feeder, which can feed pellets evenly and prevent air or moisture getting into the cooling chamber. Cooling tank, which is the main place to cool pellets by the airflow. Outer drum, which is used to gather feed materials and hot air, equipped with an observation door to facilitate maintenance. Drive engine, which drives the counterflow cooler with the electric engine, discharge motor and shaker motor. Discharge port, where the cold air gets in and cooled pellets get out evenly.

| Model | Capacity (t/h) | Feed motor power | Discharge motor power (kw) | Shaker motor power (kw) | Fan model | Cyclone model | Size L*W*H (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| SKLN11 | 1-2 | 0.75 | 0.75(slide)0.2*2(vibration) | 0.2 | 4-72-4A/5.5Kw | 800 | 2150*1325*3050(slide)2150*1325*3450(vibration) | 800 |

| SKLN14 | 2-5 | 0.75 | 1.5(slide) 0.2*2(vibration) | 0.4 | 4-72-4.5A/7.5Kw | 1200 | 2500*1650*3200(slide)2500*1650*3600(vibration) | 1200 |

| SKLN16 | 4-7 | 0.75 | 1.5(slide) 0.2*2(vibration) | 4-72-5A/11Kw | 1500 | 2100*2000*3130(slide)2100*2000*3600(vibration) | 1500 | |

| SKLN19 | 5-10 | 1.1 | 1.5(slide) 0.2*2(vibration) | 4-72-6C/18.5Kw | 2000 | 2450*2370*3480(slide)2450*2370*3000(vibration) | 2000 | |

| SKLN21 | 8-15 | 1.1 | 1.5(slide) | 4-72-8C/22Kw | 2500 | 2800*2300*4600(slide) | 2500 | |

| SKLN24 | 8-15 | 1.1 | 1.5(slide) | 4-72-8C/30Kw | 3000 | 3100*2600*4600(slide) | 3000 |

Characteristics of counterflow pellet cooler

- It can avoid the shock cooling when hot pellets are suddenly contact with the cold air because the counterflow cooler adopts counter current as the cooling agent, which can effectively prevent the pellets from cracking.

- There is no dead angels in the cooling tank profit from the octagonal design. What’s more, the deflector or centrifugal distributor can distribute the pellets evenly in the cooling tank, which improve the cooling speed and effect.

- The discharge port runs steadily with little residues or blocking benefit by the designing of slide valve reciprocating of the discharge port.

- It has the features of good cooling effect, high cooling speed and low power consumption, easy operation and cleaning, which is because the cooler adopts air-closed feeder with large inlet air area.

- In the counterflow cooler, the air speed is between 0.8-1.5m/s, which is the most suitable speed to cool pellets, because if the cooling time is too long, the pellets will be too dry and easy to broken, on the contrary, if the cooling time is too short, the pellets can’t be dried enough and is not easy to burn.

Working principles of counterflow cooler

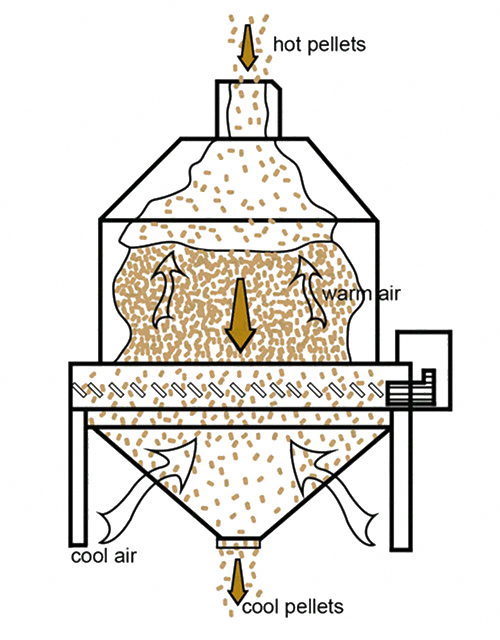

Through the airlock feeder put the pellets into the cooling tank. Then they are distributed by the deflectors or centrifugal distributors. The adjustable level sensor is used to maintain the bed depth of the materials. The cold air goes though the pellets vertically and contacts with the cold pellets. Then gradually hot air contacts hot materials, the warm air moves oppositely to the pellets dropped direction and the pellets are slowly cooled. This process avoids the directly contact between cold air and hot pellets, to prevent the cracking of pellets. Then the cooled pellets are discharged through the discharge grate uniformly and continuously in the effect of sensors and PLC system.

What should do when operating and maintaining a counterflow pellet cooler?

- Before the counterflow pellet cooler starts to work, to make sure start the air-lock device and draught fan.

- While when the cooler stops, clear the materials through the discharge port with the hand switch.

- Remember to adjust the level sensor according to your real production capacity requirements.

- Don’t open the observation door when the counterflow cooler is working.

- Lubricate the bearings and electric motor timely and regularly.

- Check the fasteners regularly to make sure if there is something wrong with them or if they are loose or falling off.

- Clean the cooler and the guide plates from time to time to guarantee the air currents run smoothly.