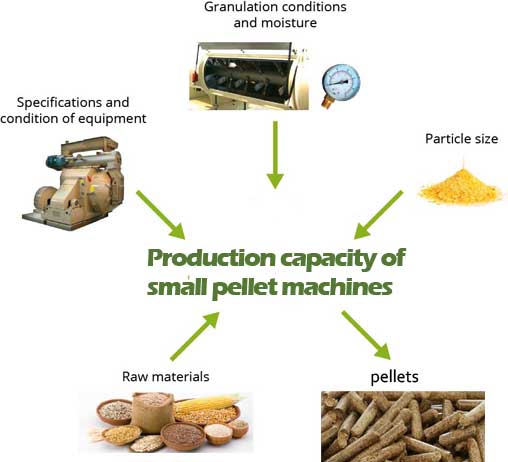

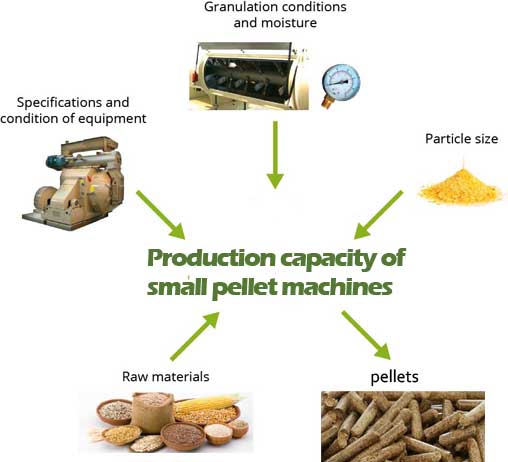

Small pellet machines take the important role in the processing of making pellets at home and especially in the wood pellet plant. It determines the efficiency of pelletizing. Production capacity of small pellet machines means how many pellets it will press the raw materials into in the unit time. This can also determine the price of small pellet machines. Hence to improve production capacity is priority among priorities.

There are many factors can affect the production capacity of small pellet machines, obviously, when we involve in the industry of small pellet machines, we would like the best results. So if we are clear that what can affect the production capacity, we can have a great efficiency. So here let’s discuss factors on small pellet machines production capacity. Generally speaking, raw material is the most significant factor which can affect production capacity powerfully. So here we put emphasis on this point.

Some issues should pay attention to

Pay attention to the viscosity of the raw materials. That is because if the viscosity of raw material is too big, it is easy to adhere to the chamber inside of small pellet machines. In case you can’t clean it up in time, will have a strong impact on the working efficiency of the pellet machines. Worse, will also affect the normal work of the small pellet machines, so pay attention to the viscosity, not too big.

Pay attention to the matching degree of flat dies and raw materials. Due to the different features of raw materials, they need different flat dies with different compression ratio to offer the proper press to make pellets finally. Only the optimum matching of compression ratio and raw materials, can guarantee the optimum efficiency.

To sum up in conclusion, the main factor which affecting production capacity of small pellet machines is the raw materials, so remind all the customers to choose suitable raw materials to process, which can not only improve the working efficiency, but also prolong the lifespan of small pellet machines and improve the quality of pellets.

There are many factors can affect the production capacity of small pellet machines, obviously, when we involve in the industry of small pellet machines, we would like the best results. So if we are clear that what can affect the production capacity, we can have a great efficiency. So here let’s discuss factors on small pellet machines production capacity. Generally speaking, raw material is the most significant factor which can affect production capacity powerfully. So here we put emphasis on this point.

- Raw material volume mass. In a general way, the larger volume mass of the raw material, the higher production capacity. So when choose raw materials, not only should consider the real needs, nutritional requirement, but also the volume mass.

- The particle size of raw material. If is fine, the surface area is larger, and the steam can be absorbed fast, which is favorable for water regulation and can have high production capacity to make more pellets. Otherwise, if the size of the raw material is expanding, will increase the wear between flat dies and rollers, which will lead energy consumption increases and production capacity decreases.

- Moisture content of raw materials. This is familiar to most of us. If the moisture content is much high, when making pellets will reduce the steam, thus will affect the improvement of the pelletizing temperature, finally affect the pellets quality and quantity. On the contrary, with low moisture content, will increase the energy consumption and intensify the wear. So the most suitable moisture content is important, generally, the proper is 10%-18%. One must make the most appropriate moisture content according to the actual situation.

- Hardness of raw materials. The harder the raw materials are, the more difficult to make pellets, the bigger pelletizing pressure will need. Plus will also increase the wear.

Some issues should pay attention to

Pay attention to the viscosity of the raw materials. That is because if the viscosity of raw material is too big, it is easy to adhere to the chamber inside of small pellet machines. In case you can’t clean it up in time, will have a strong impact on the working efficiency of the pellet machines. Worse, will also affect the normal work of the small pellet machines, so pay attention to the viscosity, not too big.

Pay attention to the matching degree of flat dies and raw materials. Due to the different features of raw materials, they need different flat dies with different compression ratio to offer the proper press to make pellets finally. Only the optimum matching of compression ratio and raw materials, can guarantee the optimum efficiency.

To sum up in conclusion, the main factor which affecting production capacity of small pellet machines is the raw materials, so remind all the customers to choose suitable raw materials to process, which can not only improve the working efficiency, but also prolong the lifespan of small pellet machines and improve the quality of pellets.