In the past 10 years, people pay more attention to the first generation of biofuels, bioethanol and biodiesel produced by cereal fodder, such as wheat, corn and soybeans etc. However, because of the consequent negative economic, social and environmental impacts, people have to find ways to turn these biomass wastes around us into as much energy as possible for human use. In turn, the liquid biofuels market has been slow to develop.

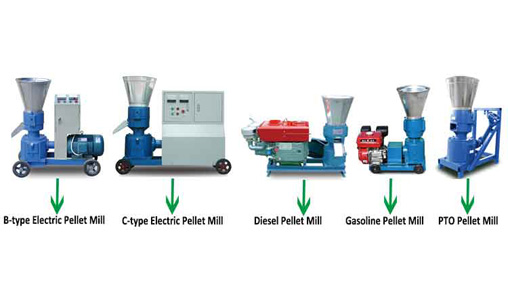

Another key cause for concern is that a shift in grain production from food supply to transport biofuels could lead to higher food prices and less food crops, particularly in developing countries. At this time, biomass waste into energy, biomass pellet machines meet new opportunities. Our company keeps pace with the times and produces biomass pellet machines to meet the need of the society.

Of course, there are also another question about how to turn biomass wastes into energy? Our company develops a kind of pellet fuel forming equipment namely pellet machines according to the market demand for the production of various kinds of biomass fuels. which is convenient to use wood powder, sawdust, rice husk, bamboo dregs, straw, hickory husk, and other agricultural and forestry wastes as raw materials. Biomass pellet machine has solved the problem of many kinds of coarse fiber, soft fiber is difficult to granulate and the effect is poor, it has been widely used by customers, the product performance is stable, and the output is high.

Characteristics and advantages of biomass pellet machines

- Vertical feed, uniform distribution, directly in place.

- The mould is still, the press wheel rotates, the material is centrifuged, the main drive adopts the high precision gear drive.

- Mould two layer, double use, double use to reduce the cost, increase the benefit of high yield.

- Ring mould, vertical structure, which is favorable for the heat dissipation and cooling of particle chamber.

- The independent frequency conversion feed system, the motor positive and negative operation to ensure the stability of the feed.

- The overall structure of the equipment is compact, the noise is low, the fault is low, the occupation area is small, the security is high, the stability is strong.

In recent years, the production and marketing of the pellet machinery industry in China have maintained an obvious growth momentum. The biomass pellets produced are also widely used in factories, chemical plants, power plants, biomass burning plants, etc. The conversion of biomass waste to biomass pellets not only reduces environmental pollution, but also reduces the use of non-renewable resources in China. With the development of technology, the technology of biomass pellet machine and the comprehensive utilization rate of bio-energy are improved. Biomass pellet machine equipment industry will also be a peak.